In the realm of transportation, a seismic shift is underway. For decades, the internal combustion engine (ICE) has reigned supreme in the vehicle industry. However, its dominance is waning as electric vehicles (EVs) surge in popularity, offering a sustainable and environmentally friendly alternative. According to Fortune Business Insights, the Indian electric vehicle industry is projected to grow at a staggering rate, reaching $113.99 billion by 2029.

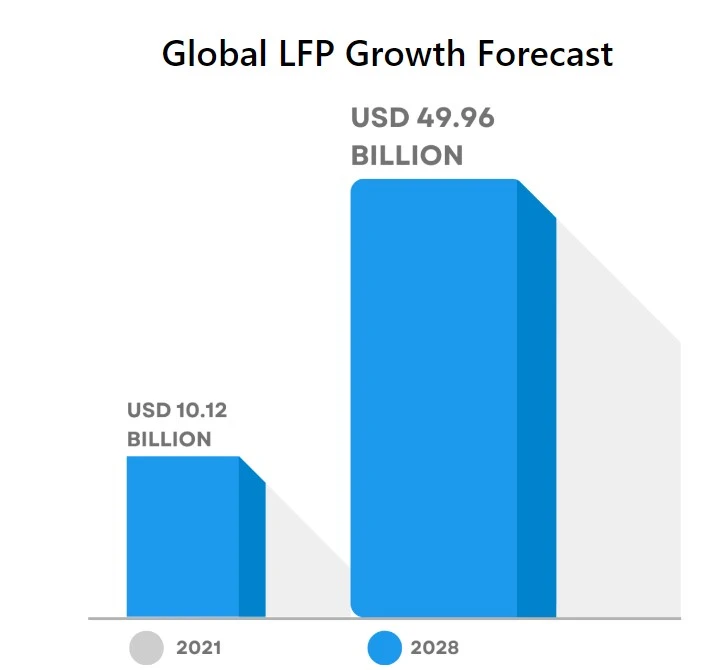

The rise of EVs is propelled by advancements in battery technology and charging infrastructure, appealing to consumers seeking to reduce their carbon footprints. Yet, widespread adoption hinges on further innovations in battery technology, production efficiency, and affordability. Enter lithium ferro phosphate (LFP) batteries, poised to revolutionize the automotive sector globally

While lithium-ion (Li-ion) batteries have been the go-to power source for EVs, they come with limitations. Li-ion batteries are prone to thermal runaway, a dangerous state triggered by overheating, and their extraction poses environmental concerns. In contrast, LFP batteries offer a compelling alternative. With a longer lifespan, inherent safety due to stable chemistry, and environmentally friendly ingredients, LFP batteries are reshaping the EV landscape.

AI Innovations in Electric Vehicle Technology

Despite slightly lower energy density compared to Li-ion batteries, advancements in design and AI-driven optimization are bridging the gap. The role of AI in EV production is pivotal, driving improvements across various fronts such as:

Design Optimization:

AI algorithms analyze vast datasets to optimize LFP battery integration during the design phase. This optimization enhances energy utilization, weight distribution, and aerodynamics, crucial for maximizing range and performance in LFP-powered EVs.

Manufacturing Efficiency:

AI-powered robotics and automation revolutionize EV manufacturing processes, ensuring precision and quality. Intelligent devices perform tasks with unparalleled accuracy, reducing human error and enhancing reliability. AI-driven quality control systems inspect parts and LFP battery packs during assembly, preempting flaws and ensuring seamless production. Predictive analytics enable proactive resource allocation, mitigating supply chain disruptions and ensuring timely delivery of electric automobiles.

Enhanced Battery Performance and Longevity:

AI continuously monitors LFP batteries, providing insights into their health. By optimizing temperature regulation and charging processes, AI maximizes battery performance while minimizing degradation. Battery management systems driven by AI not only ensure optimal performance but also extend battery lifespan, reducing replacement costs for EV owners.

The synergy between AI and LFP batteries heralds a sustainable future for EV production. AI streamlines processes, optimizes design, and enhances battery performance, driving the creation of more affordable, sustainable, and efficient electric vehicles. As AI algorithms advance and LFP battery technology evolves, manufacturers can anticipate even greater strides in the years ahead. By harnessing AI to improve battery technology, EV manufacturers accelerate the transition to a greener and more sustainable transportation sector.

1 thought on “Electric Evolution: The AI-Powered Future of Electric Vehicles”